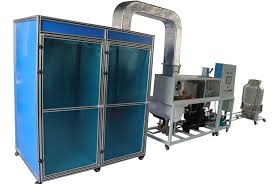

The vocational training equipment central air conditioning trainer teaching equipment can simulate the real process of building a central air conditioning system. The vocational training equipment central air conditioning trainer can demonstrate the "summer refrigeration cycle" and"winter heating cycle" process of the central air conditioning. The system of the vocational training equipment central air conditioning trainer teaching equipment includes the electrical control system and central air conditioning system. The students can learn various skills of central air conditioning system design, load calculation, electrical design, piping design, energy management, and cost estimates through the teaching equipment of the central air conditioning trainer.

Technical parameter

1. Dimension: 6000><1200><2200mm ( LxWxH )

2. Power supply: AC380V,50Hz,26.5KW

3. Cooling capacity: 27.5KW

4. Heating power: 2.0KW

5. Flow rate: 700m3/h

6. Refrigerant: R22

7. Safety protection: Overvoltage, over-current, overload, leakage, and grounding.

Product Description

This trainer includes an electrical control system, central air conditioning system, and cooling tower, which can simulate and demonstrate the summer cooling cycle and

winter heating cycle of central air conditioning. The students can learn skills such as central air conditioning system design, troubleshooting, etc.

Training courses:

1. Understand the structure and composition of the central air conditioning

2. Starting and stopping the central air conditioning

3. Running and adjustment operation of the central air conditioning

4. Testing the running conditions and running parameters of the central air conditioning

5. PLC for advanced programming and PLC installation, wiring and commissioning

6. With pressure transmitters, temperature sensors, and the corresponding Al D conversion module, entire operating parameters collection, real-time monitoring, and

other training

7. Achieve functions like the animated show of central air conditioning running, show running data, real-time monitoring, curve analysis, show historical records,

alarm, print the configuration

8. Training of network remote control

9. Training in network installation and setting up

10. Training in the installation and use of sensors and transmitters

Fault analysis and troubleshooting

1. High pressure protection

2. Expansion valve clogged

3. Compressor does not work

4. Fans of a combination of wind cabinets do not turn

5. The condensing tower fan does not turn

6. Simulated boiler does not work

7. Cold water pump does not work

8. Hot water pump does not work

9. Condensate pump does not work

10. Refrigeration control computer sensor head does not work

11. Computer-controlled analog boiler sensor probe does not work

12. Adjustment of the expansion valve is not normal

13. Compressor overload

14. Compressor starting capacitor does not work

15. System fan does not turn

16. Cooling water is not circulating

17. Heating water is not circulating

18. Refrigeration compressor contactor is not normal

19. The analog boiler heating contactor does not work

20. Condensation tower fan motor losses phase